Work safety: the system for cheking the phase of the work with the lathe

Computer vision

Сhallenge

01/

The more employees there are in manufacture, the more difficult it is to monitor, how they comply with industrial safety rules. One of these rules – is the rules of work at the lathe.

Automate the monitoring of compliance with the safety rules of the employee's work at the lathe.

Task

The system for determining the phases of work with the lathe in real time and an interface for reporting and management.

Solution

Who is the target audience

Any production facilities and workshops where there is work on the lathes, processing machines and complex equipment.

How it works

02/

Determines by the frames the staff member and the phase of the machine operation. For example, an employee looks into an open machine window

It checks, that the same staff member is in the series of pictures

If the employee breaks the rules of work, the incident is recorded

The incident card is created in the web-interface

The responsible person can look at the information and decide what to do with it

Takes frames from the video stream with the certain frequency

The system receives data from several cameras at once

Development process

03/

Collecting of business requirements

Step 01

We collect videos and photos for markup — we get them from the customer.

Step 02

We make the markup

Step 03

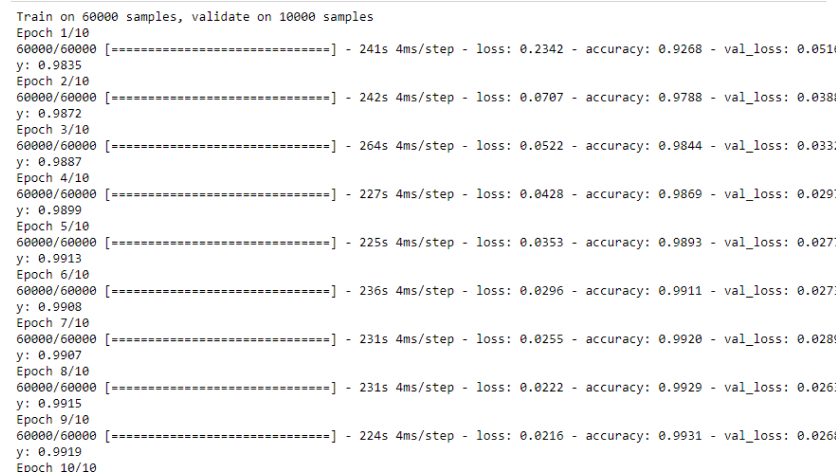

We train the detector and classifier

Step 04

We implement the model in the interface: web, desktop or somewhere else, depending on the customer requests.

Step 05

Renderings

04/

The interesting fact

The process of training the model on new data, markup, and customization of our web-platform will take approximately 1000 hours.

Tools

06/

Keras

The open library for deep learning.

ORI MarkUp

Our internal data markup tool.

Contact us