Work safety: The system for checking at the manufactures

Computer vision

Сhallenge

The more employees there are in manufacture, the more difficult it is to monitor, how they comply with industrial safety rules. For example, whether employees always wear helmets, glasses, uniforms. Do they follow the rules of working at the lathe, etc.

Solution

A real-time video incident recognition system and an interface for reporting and managing of violations.

Automate the monitoring of industrial safety in production, monitor in real time and receive reports.

Task

01/

What can be checked?

The set depends on the specifics of the customer.

Do all employees use personal protective equipment: helmet, mask, glasses, uniform, gloves and etc.

Does the employee comply with the regulations: does he handle the equipment correctly.

For whom is it useful?

For any production — in workshops and on the street — where strict compliance with safety regulations is necessary.

02/

03/

How it works

The system receives data from several cameras at once

Takes frames from the video stream with the certain frequency

Checks that the same person is in a series of pictures

If employee violates the rules of work, the incident is recorded

The responsible person can look at the information and decide what to do with it next

The incident card is created in the web interface

Determines by the frames the staff member and the necessary zones, for example, the head.

Classifies objects in the selected zone. For example, the presence or absence of the helmet or mask.

The model builds a prediction

We take a specific grid layer

We are building a heat map based on the prediction on this layer.

The visualization of decision-making by neural network

04/

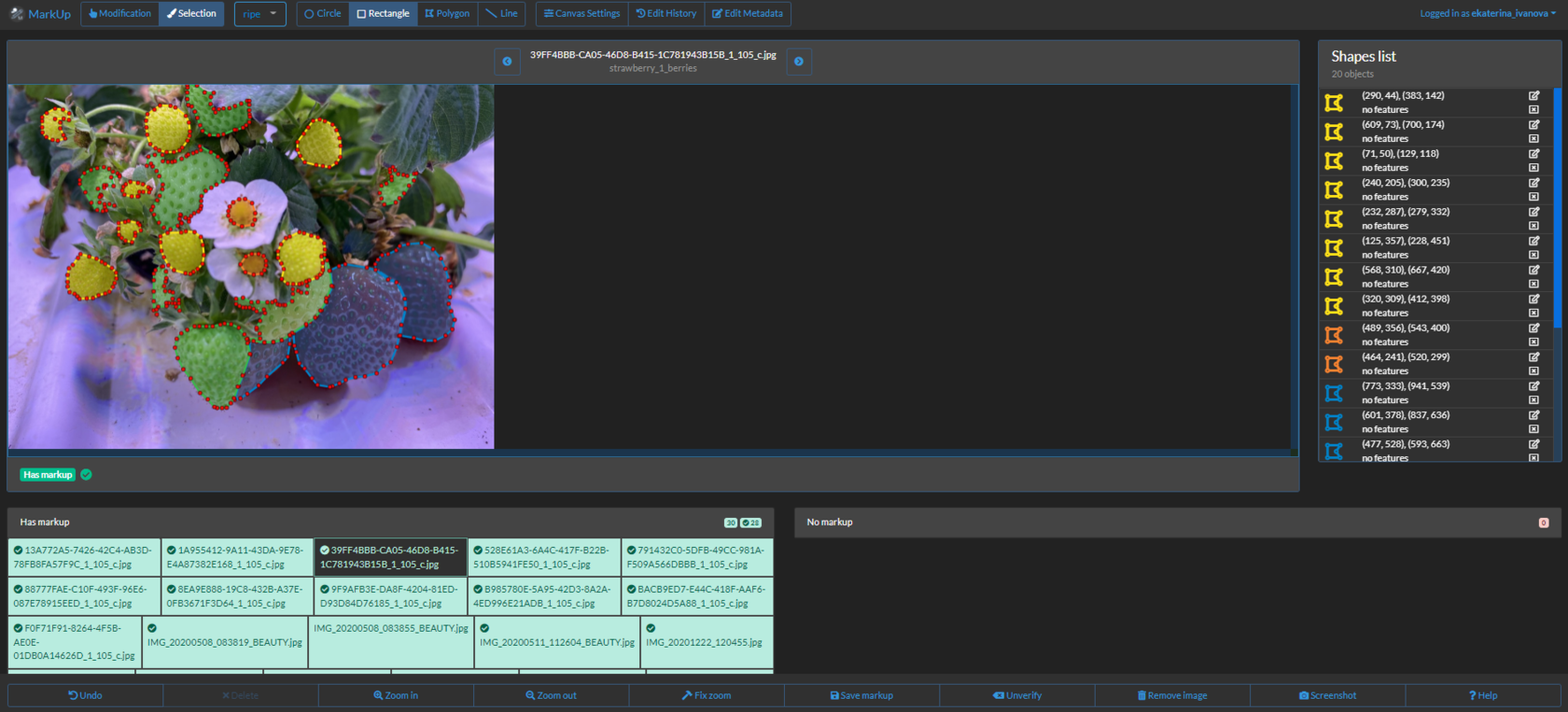

We have developed our own pipeline, which allows you to prepare markup faster.

Developed a modular architecture, taking into account that customers can be different.

We have built into our markup tool the ability to manage to complex markup: consider different types of personal protective equipment.

We have learned to monitor the work speed of the system in detail at each stage.

What we have learned

05/

Interesting fact

We can do not only on the server, but also run in a more offline and mobile format, even if there is no unified network yet.

Sergey Solovyov

Teamlead

Valery Shlyapnikov

Teamlead

Teamlead

Maxim Lukin

Project team

06/

Framework of the machine learning. Deepest learning:)

PyTorch

Our internal data markup tool.

ORI MarkUp

Tools

07/

Contact us